Our recommendations are made independently through Research & Testing. We may receive commissions from purchases made via our links.

Ice Quality for Bullet Ice Makers

Portable ice makers are convenient. All you do is fill the water reservoir and press start. However, there are some key things to know about making quality ice. Our ice quality test is scientifically based and independent so you can be sure which machine is the best for you.

This test is part of How We Test and Grade Portable Bullet Ice Makers v1.0

Portable or countertop ice makers come in a number of designs which make specific types of ice. Generally, the most affordable type of countertop ice maker is a bullet ice making machine. These typically make small and large ice bullets. Our ice quality test focuses on the large ice bullets since these are generally preferred to the smaller ones and are a better measure of the machine's best performing benchmark.

How Are Ice Bullets Made?

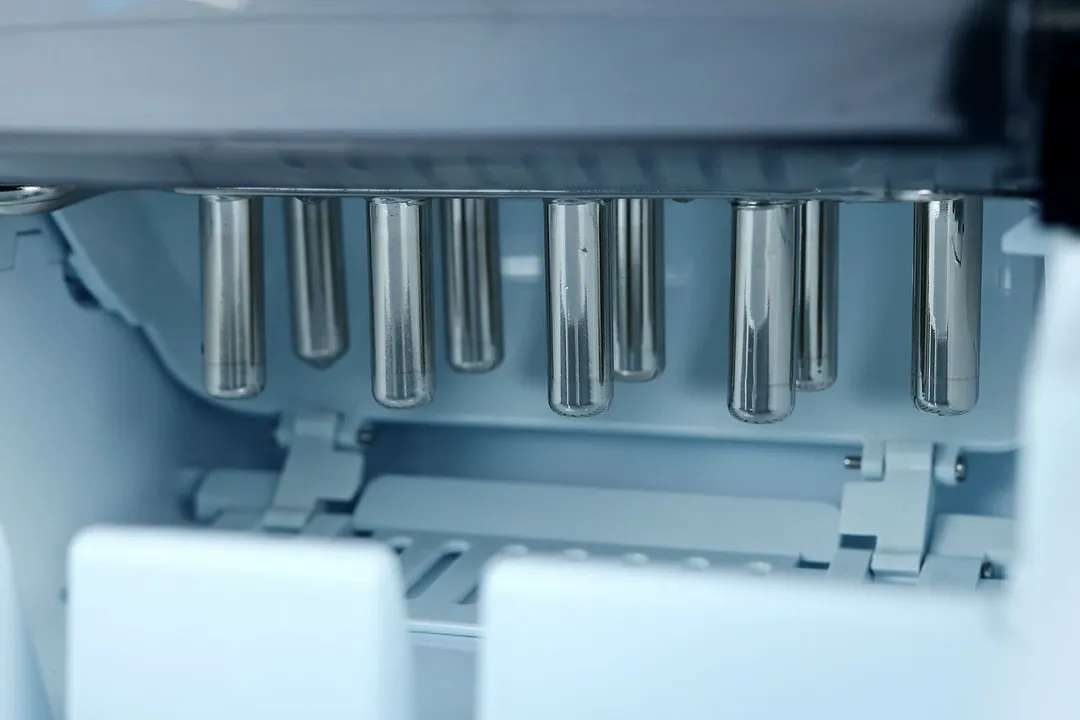

Ice bullets are formed around fingerlike rods that directly freeze water that surrounds and touches them. The process is relatively straight forward:

- Water is pumped from the reservoir into the upper water trough.

- The rods partly lower into the water trough.

- A heat exchange process begins rapid freezing.

- Freezing continues until enough ice is formed.

- The water trough hooks back and empties.

- The heat exchanger reverses and ice drops off the heated rods.

- The ice scoop, attached to the trough, scoops the ice into the basket.

Small Ice Bullets vs Large Ice Bullets

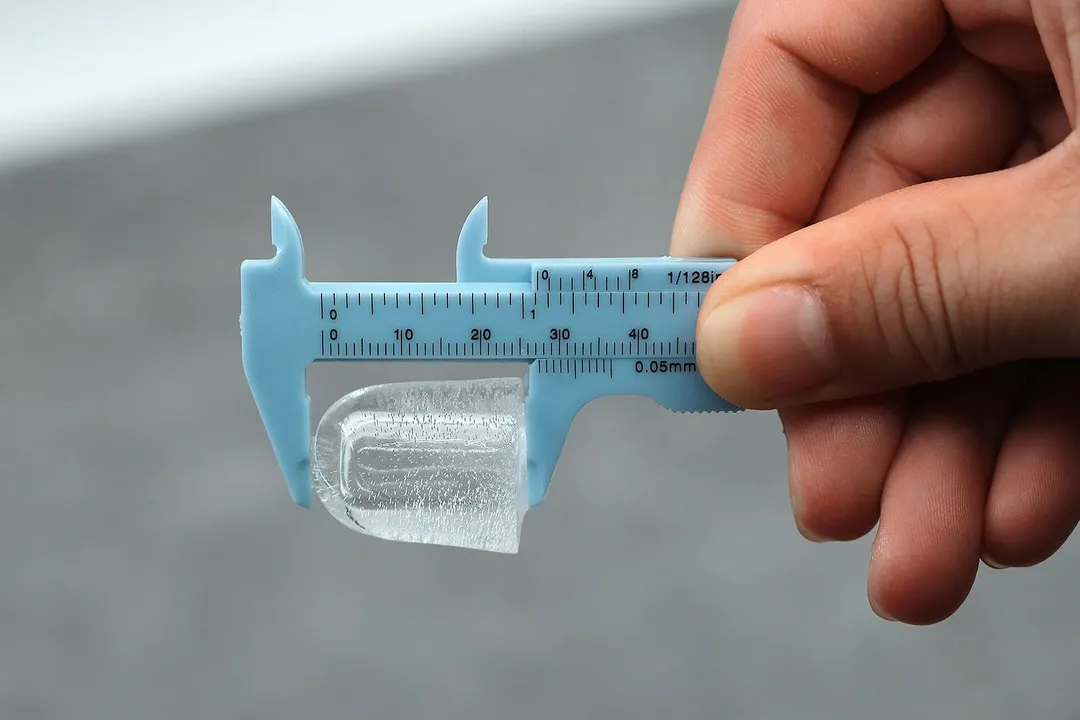

Although we run tests for both small and large ice bullets, we score the machines solely on the quality of the large ice bullets produced. Large ice bullets are thicker and give a better representation of ice quality.

Large ice bullets:

- Between 5 to 8 grams.

- Best for ice teas, smoothies, sodas, and similar beverages.

Small ice bullets:

- Between 2 to 5 grams.

- Best of ice beds for seafood, beer, or other beverage containers.

Water Quality and Ice Making

To correctly assess ice quality, the quality of the water is important. Commercial ice makers typically need an in-line water filter to regulate the quality of water, especially its hardness and level of total dissolved solids (TDS).

Refrigerators with an ice machine or water dispenser will usually have a specialized refrigerator water filter.

Bullet ice makers generally do not make any recommendation concerning water quality and filtration. It makes sense, however, to be selective about the quality of water you pour into the ice maker water reservoir.

For our tests, we use the ZeroWater pitcher filter and filtered room temperature water at around 26.7 ℃ (80 ℉). This water has a TDS level of zero. This ensures that each ice making cycle is not affected by sudden (although unlikely) changes in water quality.

For ice-making in general, it is recommended to use water that has less than 50 ppm TDS. Filtered water that is low in TDS can also extend the life of your ice maker.

Tip: How To Get Clear Ice

If you want to get perfectly clear ice, then it is necessary to use filtered water with a low TDS level. This is also one reason why we chose to use ZeroWater for our ice making tests.

There is some concern about demineralized water in that it’s not the best water for consumption. However, to date, there is no collection of data to suggest that low TDS water had adverse cumulative health effects.

For ice, and especially for our ice tests, we feel that zero TDS water is not really an issue. However, you may want to choose a different grade of filtered water for your own personal consumption.

Our Ice Quality Testing Procedure

As mentioned, we use zero TDS filtered water to till the tank of each ice maker. We also use room temperature water of around 26.7 ℃ (80 ℉). Most manufactures state that their ice maker should run in a room temperature of 50 ℉ to 90 ℉ (10 ℃ to 32 ℃). If the room is too hot, machine performance is adversely affected. We test all ice makers in an air conditioned room of 25℃ (70 ℉).

- TDS level: 0 ppm

- Water temperature: 25 ℃ (70 ℉)

- Room temperature: 10 ℃ to 32 ℃ (50 ℉ to 90 ℉)

After setting up each machine, we then select for large ice bullet making. Our test procedure is very simple. Each machine has nine ice rods. After each ice making cycle the ice will fall off the rods and the scooper will scoop the ice into the basket.

We quickly remove the ice into a small dish to weigh on a scale. We then calculate the average net weight of each ice cube. We also record the time each ice making cycle takes.

- Time per ice making cycle

- Net weight of ice

We run this test through 15 cycles of ice making and carefully record the results for analysis and also videotape the process for quality control.

Parameters for Grading Ice Quality

We have found that large ice bullets vary in size from 5 to 7 grams as an average. Some machines we have tested have produced bullets of 8 to 9 grams, but not as a consistent general average. A select number of large machines actually have three ice bullet sizes.

Manufacturers like to claim that you can have ice ready in 8 to 13 minutes. However, it takes even the best of machines around 5 to 7 waves of ice making before you get ice bullets that weigh 5 grams or more on average.

Once your ice maker ‘gets into the groove’ you can get ice bullets that weigh as much as 7 grams or higher. Rarely will a full-sized machine drop the average ice bullet weight below 5 grams. Compact machines often only produce large bullets between 4 to 5 grams.

One way to speed things up is to put chilled water of around 10 ℃ or slightly more into the tank. We start our testing with room temperature water of 25 ℃ in order to test performance from the ground up.

How We Score for Ice Quality with Bullet Ice Makers

The time we calculate for each ice making cycle is when ice is deposited into the basket and the ice making mechanism recalibrates. We measure 15 to 20 continual cycles and calculate the net average weight per ice wave.

From the point where the machine stabilizes to a consistent net bullet weight—usually 5 grams per bullet or above—we measure the average weight per bullet and score to a benchmark of 7 grams.

- 7 g = 10 pts

- Average bullet weight x (10/7) = Net score

For every ice wave that is less than the stabilized average we subtract 0.05 pts from the above score. This is to reward machines that are able to get up to standard faster and work consistently well.

- Net score - (0.05 x no. Ice waves < 5g) = Final Score

The ice quality test is one of two tests we do to gauge performance. This test counts for 40% of the total score where the ice capacity test is 60% of the score. Our ice capacity test incorporates an additional quality check since we discard badly formed or broken ice and also penalize this to the net final score.

Issues Encountered During Testing

Occasionally, with some machines, one or more ice bullets failed to fall off the rods. This was quite rare, but the bullets always fell off as they should in the subsequent ice making wave.

Most machines build up a generally good momentum, but with a few machines the average ice weight did drop a couple of times below the established minimum threshold. We penalized these instances in our scoring system.

Once an ice maker gets going, the temperature of the water in the ice basket starts to decrease which contributes to faster and better ice making. Half way through our preliminary test cycle we topped up the tank with room temperature water to see what would happen. As expected, the quality of the ice decreased in overall weight and it took two or three ice making cycles to restabilize above the usual 5 grams per bullet point.

Thus, for our ice quantity performance test, we made sure to refill the tank with refrigerated water of around 10 ℃ (50 ℉) in order to keep up the ice making momentum.

References:

- Demineralization of drinking water: Is it prudent? - https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4223198/

- Consumption of Low TDS Water - https://wqa.org/wp-content/uploads/2022/09/2015_TDS.pdf

- TDS and pH Fact Sheet - https://www.safewater.org/fact-sheets-1/2017/1/23/tds-and-ph

Test Developers

Roger Shitaki is a writer, author, and editor. His niches are household appliances, health & wellness, and travel. He’s a freelance contributor to a Tokyo lifestyle website and a leading ophthalmology magazine in Asia.

Lap is Head of the Research, Testing, and Review Team (RTR Team) at HealthyKitchen101.com, where he directs and supervises the testing of kitchen gadgets and appliances.

Nguyen Ntk is a graphic designer, photographer, and videographer whose philosophy centers around respecting and celebrating the beauty of reality. Through his lenses, Nguyen strives to capture the true essence of objects and events, showcasing and highlighting authentic features without distortion or exaggeration.