Our Manual Knife Sharpener performance TestMaterial Retention

Material retention in this context refers to a sharpener’s ability to preserve the blade’s existing material while sharpening it.

Steel removal is inevitable during sharpening. However, some devices peel off more of the blade than necessary. The upshot is that these devices tend to take less time to achieve sharpness; on the other hand, they also reduce the width of your knife and change its overall shape.

We collect and compare the amount of metal dust and particles produced by each sharpener after bringing a knife to Level 6 on the Practical Sharpness Scale. The less steel a sharpener shaves off the blade, the better rating it gets.

Why Material Retention Matters

While small blades have their uses, you don’t want to shave your knives into new shapes.

As a blade narrows, its lifespan is reduced. A smaller blade will be less rigid and will have more difficulty chopping thick and dense materials. Scooping food off the cutting board will also be a challenge.

When sharpening with pull-through sharpeners, many people tend to skip the finger guard or heel of the knife. Over time, this creates a wave near the heel, which only becomes more pronounced if your device removes a lot of material. This may affect some cutting tasks, such as the slicing of thick vegetables, since the broader part of the blade will touch the board first, preventing the narrower part from going all the way down.

A decrease in blade weight also changes the center of gravity, and thus the knife’s balance point. If it was originally balanced at the bolster or heel, it will now become handle-heavy. Depending on the task at hand, cutting with the knife may become more challenging.

Material retention makes up 25% of the Performance score.

Why Some Devices Remove Less Steel Than Others

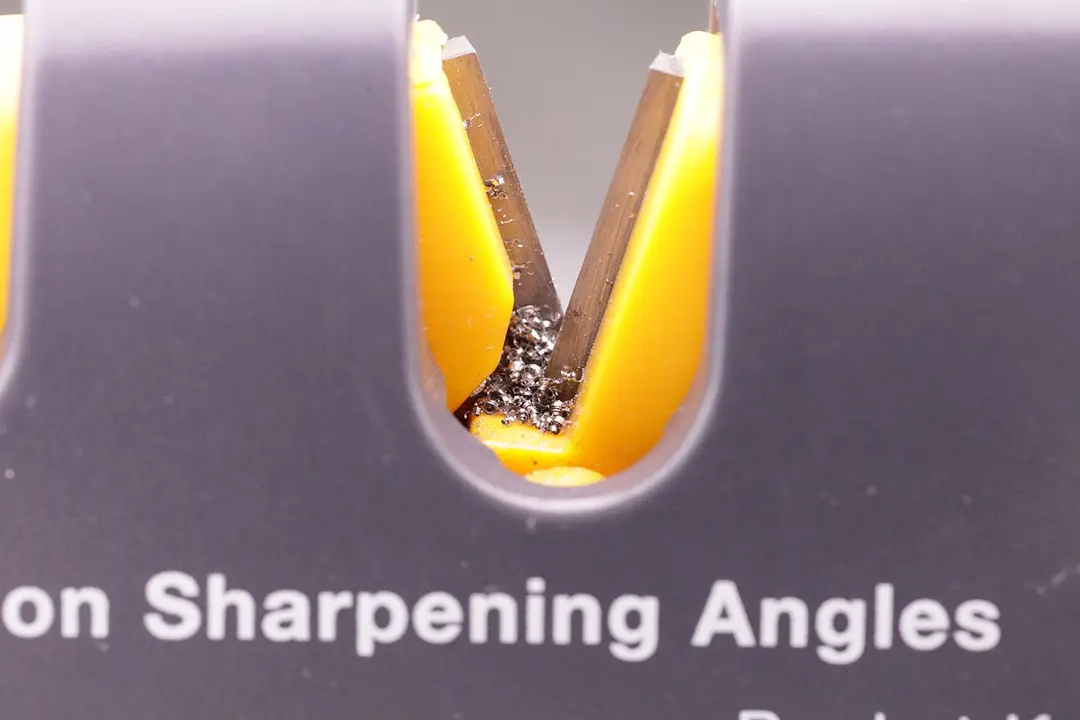

Most pull-through sharpeners feature a sharpening slot with two tungsten carbide blades. These peel off burrs, deformities, and along with them, some of the knife’s useful steel.

Some sharpeners include other abrasives. Three-stage units will usually have a slot with diamond rods preceding the tungsten carbide and one with ceramic rods that follows it. These help remove burrs, straighten the edge, and create a finer, smoother edge. They sharpen the knife while reducing the need to peel off valuable metal.

The Test

Step 1. We prepare the test knives, making sure they’re all at the same edge angle (20 degrees) and have the same level of sharpness. Next, we run the knives across sandpaper for 1 minute to blunt them. We test the edges on printer paper to make sure they’re all equally dull.

Step 2. We run each knife through a sharpener for 1 minute.

Because the slot with tungsten carbide blades does most of the peeling, we skip any slots that come after it. Sharpening slots that come before are employed since they may serve to straighten the edge and reduce the amount of steel removed by the carbide blades.

Step 3. After sharpening, we turn the device upside down, shake it, and use a toothbrush to sweep all the dust and particles onto a piece of printer paper. Our digital scales aren’t precise enough to measure such small amounts, so we go with visual inspection. Photos are taken for each device.

Scoring

We rate the material retention of the device on a scale of 1 to 10. A score of 1 indicates that the device removes a lot of material from the blade during sharpening. A score of 10 means the device can bring the knife to workable sharpness with minimal removal of steel.