Our recommendations are made independently through Research & Testing. We may receive commissions from purchases made via our links.

Raw Fish Scraps for Garbage Disposals

Uncooked fish bones are the toughest food scraps out there. In this test, we’re going to see how effective garbage disposals can be against them.

This test is part of How We Test Garbage Disposals v1.0

Can an in-sink garbage disposal deal with uncooked animal scraps such as bones and skin? And if the answer is yes, then how effectively? This test will take a close look at how these food waste grinders handle the raw remains from a fileted fish.

Why Raw Fish Scraps Matter

Herding animal bones down a kitchen disposal system might not sound like the greatest idea, but it can actually serve a purpose. It is one of the few ways of cleaning the grind chamber that all garbage disposal manufacturers recommend.

The idea here is to utilize the natural toughness of bone tissue to scour the chamber and let it clean itself, so to speak. Grinding ice cubes can have a similar effect.

This technique shows up in many brands’ manuals, though none mention whether the bones should be cooked beforehand. Since we put cooked ones through during our Scraps Mix Test, we chose to use raw bones for this one.

As expected, uncooked bones and other raw tissues were more challenging to grind. Our team got to see the capabilities of these machines from a different angle and what a good disposal can really do.

The output mass of bone tissues appeared similar to what we saw from the Scrap Mix test. The material largely broke down and traveled through most models without significant problems. In contrast, soft tissues like skin appeared much tougher to shred.

Thanks to the added nuance, we were able to collate interesting data and draw firmer and more helpful conclusions.

Test Procedure

Preparation

To conduct the test, we need some equipment, most importantly two colanders that help categorize the output, and fish scraps.

List of equipment:

- Rubber cleaning gloves

- Scale

- Stopwatch

- Noise level meter

- Running water

- Drain baffle

- Garbage disposal

- (Layer 1) Shallow 18½-inch plastic colander with round holes (~ 0.08 sq in)

- (Layer 2) Deep 18½-inch plastic colander with rounded square holes (~ 0.05 sq in)

- Deep 20-inch container

We assemble a two-layer screening device with two colanders: Layer 1 on top catches large pieces and Layer 2 below catches smaller pieces. The different openings on the two layers help us separate the output samples which we then measure in step 3 for later comparison.

List of Ingredients:

- Uncooked fish scraps: ~ 49.4 oz (1380-1400 g)*

*The figures shown are for one run.

We purchase scraps of salmon that include bones, skin, and leftover meat, but without the heads. These scraps are packaged separately; each package supposedly contains one whole salmon.

Each package weighs differently, so in order to arrive at approximately the same input across all tests, we deliberately select characteristic portions that make up a whole fish and build our own set of scraps. Then, we do our best to even out the weights using the remaining bits.

Execution

- Step 1: With the splash guard in position, we put the prepared salmon scraps in the sink, and place the screening device in position underneath.

- Step 2: We run water, turn on the machine, and proceed to flush stuff down. We start the stopwatch once the first scraps enter the chamber. Each candidate will operate for 3 minutes with the scraps going in continuously. We pause the clock if a disposal gets stuck to unjam the motor. If it overheats, we wait for the circuit breaker to reset, then continue the test until time is up or the device has overheated 3 times.

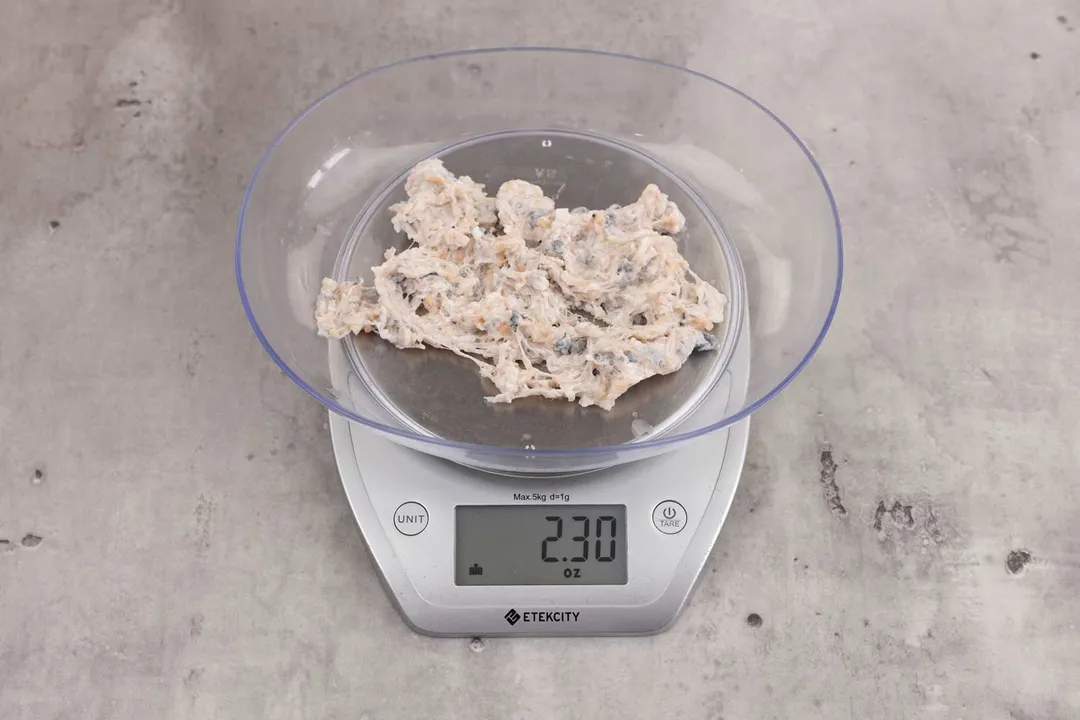

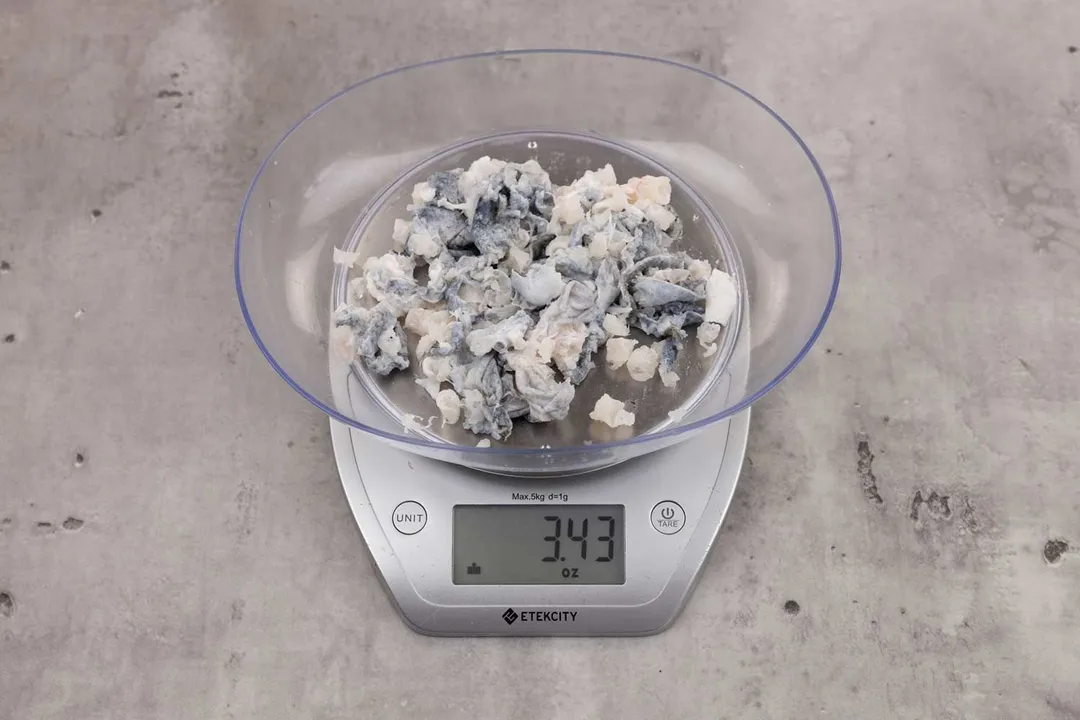

- Step 3: We turn the machine off, collect the materials that have accumulated in each layer of the screening device, and weigh each category respectively. The leftovers inside the grind chamber are collected and weighed as well.

Scoring

We rate each product based on the amount of leftovers, materials in Layer 1 (large pieces), and materials in Layer 2 (small pieces).

We set the Fail/Pass criteria as follows:

- If a candidate overheats three times, the run fails.

- If more than 10% of the input load remains in the chamber after 3 minutes, the run fails.

Since the total input weighs 49.4 ounces, a product will pass if it leaves no more than 4.94 ounces worth of leftovers in the chamber. Also, thanks to our early test runs, we’re confident that 3 minutes is a fair and sufficient amount of time for any reasonable disposal to finish the task.

Next, the leftovers, Layer 1, and Layer 2 are scored:

- If Leftovers amount to less than 1% of the input load, a candidate receives 10 points. For every 1% beyond that, it loses 1 point.

- If Layer 1 catches less than 5% of the input load, it receives 10 points. For every 2% beyond that, it loses 1 point.

- If Layer 2 catches less than 5% of the input load, it receives 10 points. For every 2% beyond that, it loses 1 point.

To sum up, a candidate scores a perfect 10 if it manages to grind through 99% of the input load while releasing less than 2.47 ounces in Layer 1 and less than 2.47 ounces in Layer 2, all in under 3 minutes.

The final product rating is weighted based on the importance of each parameter listed above. Fully 50% is taken from the Leftovers score, 30% from that of Layer 1, and 20% from Layer 2.

Examples

Let’s take a look at some of the results we collected:

- Insinkerator Evolution Excel: 9.3 points.

The final rating of 9.3 draws 5 points from Leftovers, 2.3 points from Layer 1, and 2 points from Layer 2.

- Waste King L-1001: 5.9 points.

The final rating of 5.9 draws 2 points from Leftovers, 1.9 points from Layer 1, and 2 points from Layer 2.

Test Developers

Be Nguyen is a writer and product reviewer. Being naturally curious about technology and its real-world applications, Be spent several years in university studying engineering before joining the team at HealthyKitchen101 where he disassembles, tests, and rates household appliances.

Lap is Head of the Research, Testing, and Review Team (RTR Team) at HealthyKitchen101.com, where he directs and supervises the testing of kitchen gadgets and appliances.

Nguyen Ntk is a graphic designer, photographer, and videographer whose philosophy centers around respecting and celebrating the beauty of reality. Through his lenses, Nguyen strives to capture the true essence of objects and events, showcasing and highlighting authentic features without distortion or exaggeration.