Our recommendations are made independently through Research & Testing. We may receive commissions from purchases made via our links.

Raw Chicken Scraps for Garbage Disposals

Grinding chicken bones helps clean the inside of garbage disposal. However, if the bones are uncooked, the task can be a challenge to some models.

This test is part of How We Test Garbage Disposals v1.0

Leftover chicken bones are among the most common kitchen scraps. They’re also some of the toughest. It’s natural to wonder if your sink’s garbage disposal can take care of them. In this test, we’ll be focusing on what an in-sink food disposal system can do with uncooked scraps from defleshed chicken thighs.

Why Raw Chicken Scraps Matter

Going through the different manuals, we found that manufacturers actually recommend that you grind animal bones now and then to help clean the grind chamber.

The idea is that the hard, sharp corners of crushed bone tissue will scour the chamber’s interior. If you have heard about cleaning by grinding ice, this works on the same principle.

For this test, we decided to use chicken bones — specifically raw scraps that remain after deboning the thighs — because of how common they are.

Our Scrap Mix test also included materials from deboned chicken thighs, but those were all cooked. This time around, we aim for the other end of the spectrum and let these in-sink grinders go up against uncooked bones, instead.

From the results, we find that, much like the cooked ones, uncooked bone tissues break up and go through the grind chamber without noticeable hiccups. It’s actually the soft tissues that spring up trouble. Raw skin, tendon, and cartilage are fibrous and spongy, so even some of the top disposal systems need significantly more time and water to process them.

Test Procedure

Preparation

In this test, we mainly focus on the time it takes for every product to break down all the non-fibrous tissues from the input load, i.e. the bone and the cartilage. We also assess what comes out the other end and assign scores based on the grind’s general permeability.

List of equipment:

- Rubber cleaning gloves

- Scale

- Stopwatch

- Noise level meter

- Running water

- Drain baffle

- Garbage disposal

- (Layer 1) Shallow, 18½-inch plastic colander with round holes (~ 0.08 sq in)

- (Layer 2) Deep, 18½-inch plastic colander with rounded square holes (~ 0.05 sq in)

- Deep, 20-inch container

The two colanders are stacked upon one another to make a two-layer screener. The shallow colander with larger holes is meant to catch large pieces of ground materials while the deeper one with narrower holes is for the smaller pieces. Samples on each layer get weighed and scored.

List of Ingredients:

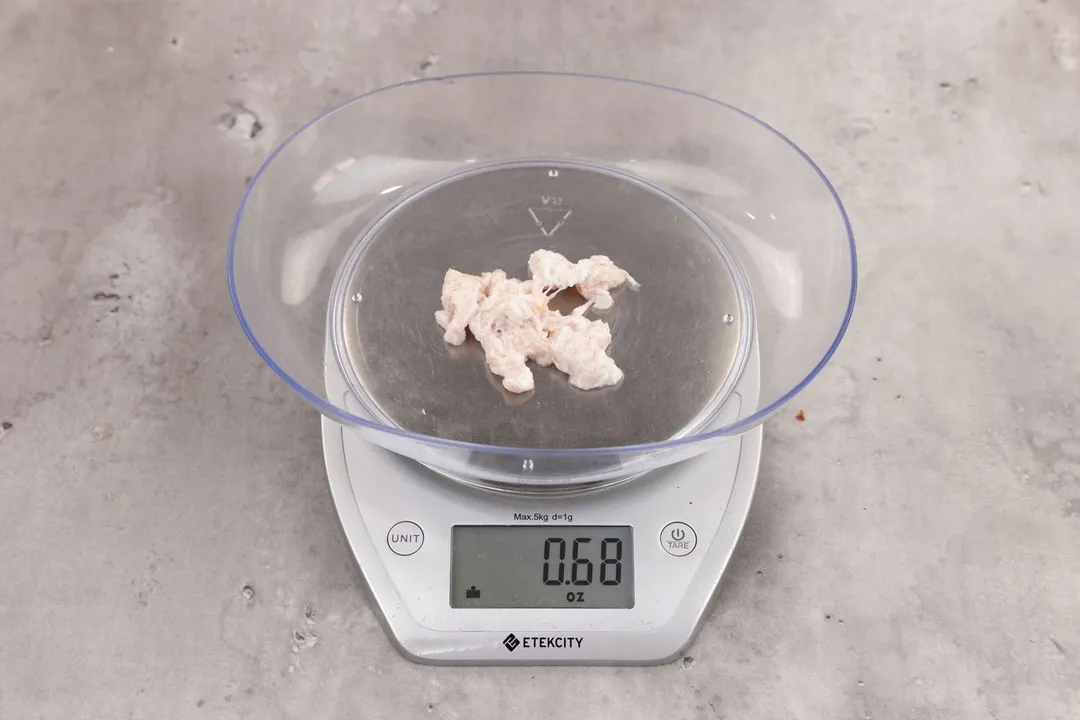

- Uncooked chicken (thigh) bones: ~ 7.4 oz (205–215 g)*

*The figures are for one run.

The bones we bought came in packages of various sizes and weights, so we had to make adjustments here and there (cutting out extra skin or scraping remaining meat from the bones) to make sure that the input load was approximately the same across the board.

Since it’s impossible to even out the portions of skin and other soft tissues across all batches, we increase the number of bone pieces and let those other factors balance themselves out. For every run, we aim to test 4 sets of bones, with each set of two joined leg bones* weighing about 1.85 ounces (51-54 grams). In total, each run requires approximately 7.4 ounces (205-215 grams).

*We purposely look for sets of thigh bones that have not yet been separated so we can test out the verticality of each disposer.

Execution

- Step 1: With the splash guard and the container in position, we put the prepared chicken scraps in the sink.

- Step 2: We run the water, turn on the machine, and proceed to flush everything down. We start the stopwatch once the first scraps enter the chamber. A run finishes when most of the tough tissues have been processed*.

*We can tell by how the sound gets quieter and more uniform.

We pause the stopwatch if a disposal appears stuck so we can unjam the motor. If it overheats, we wait for the circuit breaker to reset, then continue the test until 3 minutes have passed or a disposal has overheated 3 times.

Step 3: We collect the leftovers (inside the grinding chamber) and the materials on both Layer 1 and Layer 2, then weigh them separately.

Scoring

We score each product based on the amount of leftovers, the processing time, and the weights of Layer 1 (large pieces) and Layer 2 (small pieces).

We settled on the following Fail/Pass criteria:

- If a candidate has overheated three times, the run fails.

- If more than 20% of the input load remains in the chamber as leftovers after 3 minutes, the run fails.

The input load is standardized at 7.4 ounces, so if a candidate leaves behind less than 1.48 ounces, it will pass.

Time is scored as follows:

- A candidate scores a 10 if it finishes (with less than 1.48 ounces of leftovers) in under 2 minutes.

- For every 15 seconds beyond the 2-minute mark, the candidate loses 1 point.

We set 2 minutes as the scoring benchmark since even the most capable disposers in our collection take that much time to achieve passable results.

Next, the leftovers, Layer 1, and Layer 2 are scored:

- If Leftovers constitute less than 1% of the input load (by weight), a candidate receives 10 points. For every 2% beyond that, it loses 1 point.

- If Layer 1 catches less than 5% of the input load, it receives 10 points. For every 2% beyond that, it loses 1 point.

- If Layer 2 catches less than 10% of the input load, it receives 10 points. For every 3% beyond that, it loses 1 point.

To put everything simply, a candidate scores a perfect 10 if, within 2 minutes, it manages to process 99% of the input load while producing less than 0.37 ounces of large chunks and no more than 0.74 ounces of smaller chunks.

The final rating for the test is weighted at 40% from Leftovers, 20% from Layer 1, 15% from Layer 2, and 25% from Time.

Examples

Let’s take a look at some of the results we collected:

- Insinkerator Evolution Excel: 8.5 points.

The final rating of 8.5 draws 3.7 points from Leftovers, 1.6 points from Layer 1, 1.2 points from Layer 2, and 2 points from Time.

- Moen GX50C: 6.3 points.

The final rating of 6.3 draws 2.5 points from Leftovers, 1.3 points from Layer 1, 1 points from Layer 2, and 1.5 points from Time.

Test Developers

Be Nguyen is a writer and product reviewer. Being naturally curious about technology and its real-world applications, Be spent several years in university studying engineering before joining the team at HealthyKitchen101 where he disassembles, tests, and rates household appliances.

Lap is Head of the Research, Testing, and Review Team (RTR Team) at HealthyKitchen101.com, where he directs and supervises the testing of kitchen gadgets and appliances.

Nguyen Ntk is a graphic designer, photographer, and videographer whose philosophy centers around respecting and celebrating the beauty of reality. Through his lenses, Nguyen strives to capture the true essence of objects and events, showcasing and highlighting authentic features without distortion or exaggeration.